Mechanized plastering of walls

Mechanized (it is also called machine, mechanical, automatic or automated) plaster is a relatively new product on the construction market, but it has already received a positive assessment from those who managed to use it. Previously, such plaster was applied only on a ready-made base. That is, the primer, the application of leveling layers of mortar, grout were made manually. However, progress does not stand still, and already today there are devices that perform a full cycle of work on the treatment of walls automatically.

Mechanical leveling technology is widely used in the decoration of walls, facades, and ceilings.

Automated plaster packages

| Простая

штукатурка стен | Improved plaster

Hit of sales

| High-quality plaster | VIP Package

For the most demanding

| |

| Price

| from 450 rubles/m2 | from 530 rub/m2 | from 600 rub/m2 | from 700 rub/m2 |

| Departure of the engineer | + | + | + | + |

| Signing the contract | + | + | + | + |

| Online broadcast of the object | - | - | - | + |

| Delivery of equipment and material | + | + | + | + |

| Dedusting of the surface | + | + | + | + |

| Surface priming | + | + | + | + |

| Installing beacons | - | + | + | + |

| 90 degree angles in the kitchen and in the bathroom | - | + | + | + |

| 90 degree angles in all rooms | - | - | + | + |

| Fiberglass mesh at the joints of dissimilar materials | - | + | + | + |

| Applying the mixture with a plaster station | + | + | + | + |

| Dismantling of lighthouses,

grouting of seams | + | + | + | + |

| Polishing | + | + | + | + |

| Cleaning of the premises | + | + | + | + |

| A complete set of executive documentation, including Executive diagrams with actual dimensions, indication of hidden engineering systems, acts for hidden work | - | - | - | + |

| Certificate of conformity from an independent laboratory | - | - | - | + |

| Signing of the Acceptance Certificate of completed works | + | + | + | + |

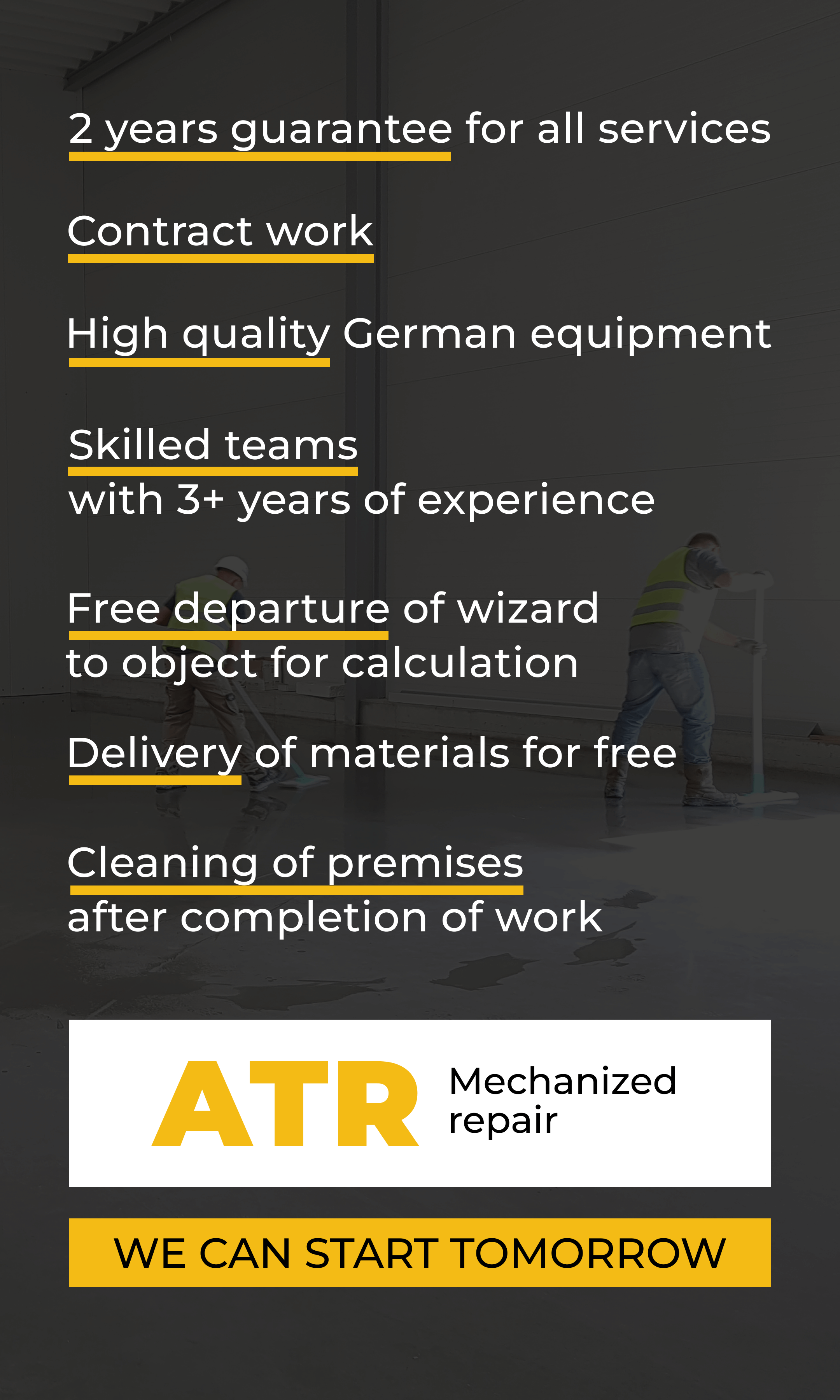

| 24 months warranty | + | + | + | + |

Advantages of automatic plastering

The main advantage of automated plaster is saving time. It allows you to process up to 150 square meters of surface per day, while attracting a minimum of resources. On average, plaster is applied in a mechanized way 4-5 times faster than traditional. Plus, it does not require multi–layer application to the base - it is enough to apply just one layer of such plaster so that the surface becomes smooth.

Another advantage of mechanized plaster is saving money. Since it does not require a large number of workers to apply it to walls, floors and ceilings, it is possible to save on their wages. One person can handle machine plaster quite well. By the way, the solution itself for mechanized application to the surface is cheaper than a mixture for manual finishing. As a rule, the difference can be up to 40%.

We use equipment from well-known manufacturers and certified materials. These are Italian and German stations and gypsum, special plaster mixtures of Knauf, Volma, Kreisel. You can read more about our equipment in the section equipment for mechanized plaster.

Plaster in a mechanized way copes well with irregularities on surfaces due to the high impact force with which the mortar comes into contact with the wall. Due to its consistency, the solution penetrates even the smallest cracks in ceilings and walls.

The automated method of plastering is suitable for any type of premises:

- Typical apartments

- New buildings

- Offices

- Country houses - cottages, townhouses

- Retail and commercial premises

- Entire buildings

- Infrastructure facilities of cities and towns

Disadvantages of mechanized plaster

One of the obvious disadvantages of this method of processing walls, floors and ceilings is equipment for its application.

Firstly, if the plaster station is electric, then it will have to be raised to the floor. If there is a narrow elevator in your house or there is no elevator at all, the task will become very difficult.

Secondly, the most common power plants operate under pressure at a power of 380V. A converter is required. In ordinary high-rise apartments, it is not always convenient and cost-effective to use them. Our company has stations for both 380 V and 220 V.For the upper floors, units with an internal combustion engine are used. Long hoses are used, through which the solution is supplied under pressure. As a rule, a lot of dirt remains after working with such stations.

Plastering process

The work on mechanized plaster consists of 3 stages.

1st stage: Departure of the engineer to the facility

At this stage, it is necessary to determine the scope of work and approximate deviations. This is necessary to determine the final cost of the project and the volume of the required solution. Also at this stage, the equipment that will be used to perform the work is determined.

What determines the choice of equipment

The choice of a plaster station depends on many factors. The main criterion is the voltage that is present on the object. If it is 220V, then machines of the PFT Ritmo type are used.

Mainly used plastering stations at 380V. They have higher productivity. These are such stations as Putzmeister MP 25, PFT G4, Maltech M5.

In the process of preparing for the production of works, it is necessary to prepare a cold water connection point.

The customer also needs a fundamental decision on the geometry of the interior corners of the room. This will save on material when plastering in a mechanized way.

Next, we select the necessary material to perform all stages of work. The process is more of an exploratory nature. We choose which type of plaster solution suits us (gypsum, cement-sand, polymer or other plaster mixture), what consistency, volume, etc. What does it depend on?

- On the material and condition of the building structure

- Depends on the functional purpose of the room. In wet areas, building facades, we use cement-based mixtures. Plaster on gypsum binder is used in dry areas. All factors are excluded and taken into account (whether the solution will shrink, what is the future finish, whether pruning is needed, etc.)

- From the finish coating. Only cement-based plaster (cement-sand, cement-lime plaster) is used for ceramic tiles, porcelain stoneware.

- From the customer's wishes. The customer draws knowledge from the Internet and believes that his knowledge is currently better than companies with more than 15 years of experience.

2nd stage: Production of works in houses and apartments

This stage begins immediately. The supply of material, the mobilization of brigades takes place in one day.

On the same day we start the production of works, prepare the surface. It is very important to observe the technology of applying the primer to the wall and ceilings and let it dry for at least 6 hours. On the first day, beacons are placed, according to the level of which the surfaces of the walls will be leveled. Beacons are placed on the wall according to the indications of the laser level.

The next day, the equipment is prepared and the solution is prepared.

Direct plastering begins: we apply the solution to the surface and pull the plane along the beacons.

After setting the mixture, the lighthouse profile is dismantled and smoothing (gloss) is performed. This is a rather laborious work process that requires certain skills and knowledge.

After that, the wall surface is ready for finishing. It remains for us to clean the premises and remove the equipment.

3rd stage: Delivery of works

After the completion of the work and acceptance, our engineer notifies the customer about the completion of the work. The act of delivery and acceptance of works is signed. From this day begins the warranty period for the work performed by our company.

Price list:

the cost of your artwork?

upon completion?*